Experimental Capability

Additive Manufacturing

EOS M290 x4

EOS M290 is a laser powder bed fusion (L-PBF)-based additive manufacturing machine. It has a build volume of 250 x 250 x 325 mm and utilizes a laser with a maximum power of 400 W. There are four EOS M290 at the National Center of Additive Manufacturing Excellence (NCAME), two at Auburn University and two at Huntsville, Alabama. These EOS M290 machines are equipped with in-situ monitoring systems such as PrintRite 3D from SIGMA Additive Solutions, EOSTATE ATE MeltPool, and EOSTATE Exposure OT from EOS. PrintRite 3D and EOSTATE MeltPool utilize the sensors integrated into the beam path to capture the light emissions from the meltpools. They give deeper insights into the fabrication process by analysing the energy input and temperature across the build volume. Furthermore, EOSTATE Exposure OT is an optical tomography-based system that utilizes heat emission data to provide cost-efficient quality assurance of the AM (Additive Manufactured) parts.

The EOS machines are equipped with Sigma Labs 3D Monitoring System.3D Systems DMP 350 Flex

The DMP 350 Flex is a robust L-PBF system designed for more flexible, high throughput production of parts. It utilizes 500W of laser power and has a build volume of 275 X 275 X 420 mm3. This system is especially useful for R&D projects, application development, or serial production. Besides, it is easily scalable for volume part production. Quick-swap build modules and fast powder recycling speed up production. Its metal AM 3DXpert is a powerful tool to prepare and optimize the parts data quickly, allowing the rapid design of production parts and shortening lead time. Due to the unique vacuum chamber concept, the consumption of argon gas is greatly reduced, which results in exceptionally strong parts.

Renishaw AM500Q Flex

Renishaw AM500Q (RenAM 500Q) Flex is an L-PBF based additive manufacturing system that utilizes four high-power 500 W lasers, each able to reach the entire powder bed surface simultaneously, to selectively melt the powder layer. With its four lasers, RenAM 500Q achieves build rates up to four times faster (up to 150 cm3/hr) than single laser systems. The system features automated powder and waste handling systems that enable consistent process quality, reduce operator intervention time, and ensure high standards of system safety. It is also equipped with an intelligent gas flow that ensures efficient removal of ejecta.

Renishaw AM250

Renishaw AM250 is an L-PBF system, which provides a 250 X 250 X 300 mm3 build volume and a maximum power of 250 W. Key features include variable powder delivery, ultra-low oxygen content in the build atmosphere, and an unparalleled safe-change filter system to minimize user contact with materials. The system has vacuum technology which results in low gas consumption. It is designed for rapid material changeover and is especially useful for R&D work.

Open Additive Machine

The Open Additive PANDA is an open architecture LB-PBF system used in various research topics. The system is equipped with a 500W fiber laser, a heated build platform (capable of going up to 500°C), and has a build volume of 152 x 152 x 241 mm. The configurable features allow more freedom to work with different types of AM materials as well as the development of new and unique processing strategies.

Coherent CREATOR

The Coherent CREATOR is an excellent small-volume LB-PBF machine that is unique in its design with a circular coater that can decrease the build time by 30%. One of the best qualities of this system is the intuitive software package provided by the machine. It is comparatively cheaper and can rapidly print parts compared to other 3D metal printers. This machine contains a small building platform which is much easier to change material systems compared to all of our other platforms. Also, it takes less time to prepare the build files, execute builds, and conduct maintenance.

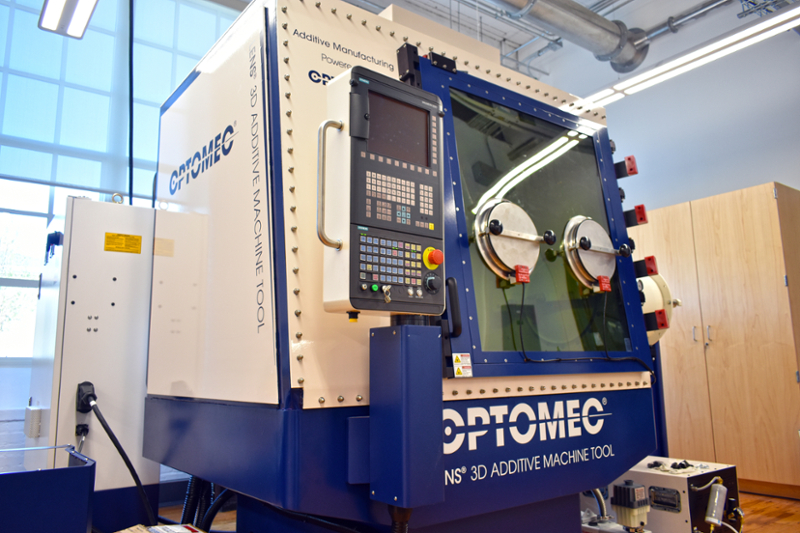

OPTOMEC LENS 3D Additive Machine Tool

The OPTOMEC LENS 3D Additive Machine Tool provides high-quality metal 3D printing with 10 times faster printing speed than Powder Bed Fusion systems. LENS uses directed energy deposition (DED) technology, where a high-powered laser beam is used to fabricate structures layer by layer from powdered metals, alloys, ceramics, or composites to produce fully-dense parts. Some of the advantages of DED are reduced manufacturing costs and materials, reduced process time, and the ability to process non-reactive and reactive metals.

Mechanical Testing

MTS Uniaxial Fatigue Testing Machines & MTS Multiaxial Fatigue Testing Machine

NCAME is the home to Two MTS Landmark 370 (Floor model), load capacity 100kN MTS 810, load capacity 100kN Two MTS Landmark 370 (Tabletop model), load capacity 25kN MTS 809 Axial/Torsion, load capacity 100kN / 1100 N*m MTS Bionix Axial/Torsion, load capacity 25kN / 250 N*m Other equipment: -Three/Point bending up to dynamic loads of 10kN and static loads of 30kN - Fatigue crack growth with CTOD gage (0.25 in) this one is included in the list of extensometers - High Temperature Testing up to 1000 °C.

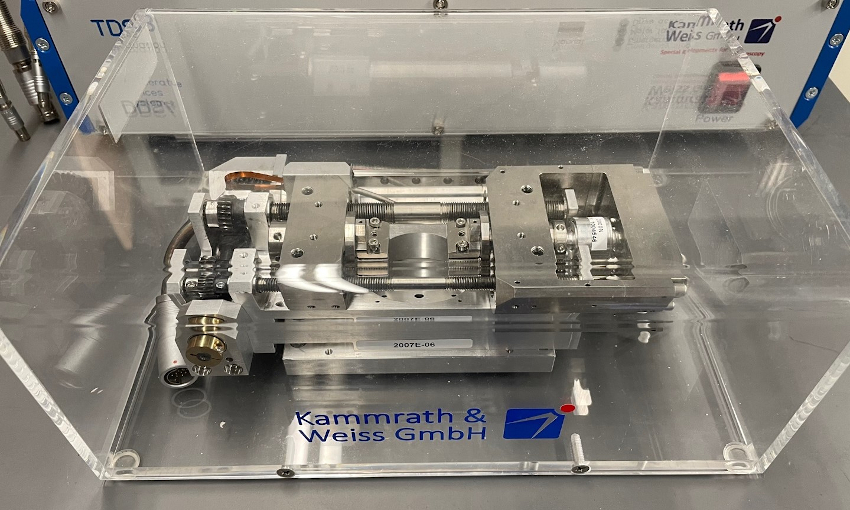

Kammrath & Weiss In-situ Tensile-Compression Module

The Kammrath & Weiss Tensile-Compression module can fit within the chamber of the scanning electron microscope and continuously apply loads through tension, compression, and zero. Tests can be run in the form of but are not limited to, quasi-static tensile tests and axial fatigue tests with sinusoidal or ramp waveforms. The benefits of this setup include real-time observation of microstructural deformation and change under loading, EBSD compatibility, cryogenic temperature testing, and programmable step loading to name a few. The module is equipped with a 2 kN load cell, that is expandable to 10 kN. Specimen size can reach a maximum of 60 x 10 x 5 mm³ for flat specimens, but other specimen types and geometries are available. The linear motor is capable of speeds up to 25 µm/s. Furthermore, a ±1 mm extensometer is available with a resolution of <100 nm.

Hardness Tester (Leco LCR-500)

Leco LCR-500 is a Rockwell-type hardness testing machine. LCR-500 Rockwell-type testing systems are built to handle high-volume workloads without sacrificing accuracy or repeatability. The perks of the LCR-500 are its ease of use, customizable Rockwell-type test using minor/major load (combinations from 3 to 200 kgf), advanced touch-screen display, LED illumination to aid indent placement on the sample, closed loop, self-compensating load cell technology.

Pace Technologies Vibratory Polisher

The GIGA-1200 vibratory polisher has a solid, easy-to-use, robust design, and utilizes a 12-inch polishing bowl. The main benefits provided by the GIGA1200 are its ability to adjust both the vibration frequency and voltage. Adjusting the vibrating frequency compensates for the weight of the specimens, being polished; thus, small, or large samples can be prepared separately or simultaneously. In addition, the speed of the polishing action can be easily controlled by changing the applied voltage. Especially useful for EBSD polishing sample preparation (electron backscatter diffraction). Polishing is accomplished by setting the default frequency so that the sample begins to vibrate and then changing the voltage in order to adjust the rotational speed of the machine.

Materials Characterization

Zeiss Crossbeam 550 Scanning Electron Microscope

The Zeiss Crossbeam 550 Scanning Electron Microscope combines the imaging and analytical performance of a high-resolution field emission SEM with the processing ability of a next-gen focused ion beam (FIB). This state-of-the-art FIB-SEM has Gemini II electron optics which ensures high beam quality for high-resolution (0.6 nm) imaging. Its 5 different electron detectors (including conventional and in-lens secondary electron detectors, in-lens energy selective backscattered (ESB) electron detector, a four-quadrant backscattered electron (BSD) detector, and STEM detector) enable truly versatile materials characterization. The microscope also has Oxford instruments onboard the FIB-SEM enabling advanced energy-dispersive x-ray spectroscopy (EDS) and electron backscatter diffraction (EBSD) analyses. This FIB-SEM, with its Ion-sculptor Ga+ FIB at an exceptional FIB resolution of less than 3 nm, also offers superb TEM sample preparation quality. In addition, its ultralow FIB voltage currently minimizes the amorphization zone of TEM lamella during the final thinning step.

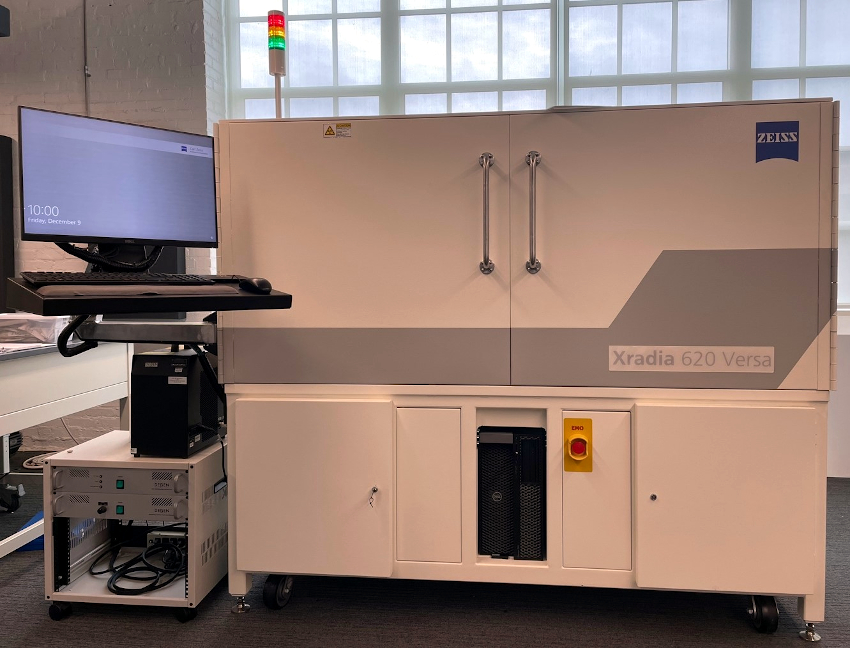

Zeiss Xradia 620 Versa X-ray Microscopes

The ZEISS Xradia 620 Versa 3D X-ray microscope provides superior 3D image quality and data for a wide range of materials and working environments. Xradia Versa XRM features dual-stage magnification based on synchrotron-caliber optics and revolutionary RaaD™ (Resolution at a Distance) technology for high resolution even at large working distances, a vast improvement over traditional micro-computed tomography. Non-destructive imaging preserves and extends the use of your valuable sample, enabling 4D and in situ studies. ZEISS is shared with CPAC.

-

- Automated, programmable filter changer

- High aspect ratio tomography

- Dual scan contrast visualization

KEYENCE VHX-6000

Superior analyses can be performed through the KEYENCE VHX-6000 series microscope. This microscope has adaptive lighting, advanced focusing, large depth-of-field, multi-angle observation, real-time measurements, improve images using High-Resolution HDR, ring reflection removal, 3D image stitching, contamination analysis, etc. KEYENCE VHX-6000 is mostly used for analyzing the fracture surfaces, porosity, and surface roughness measurements in NCAME.

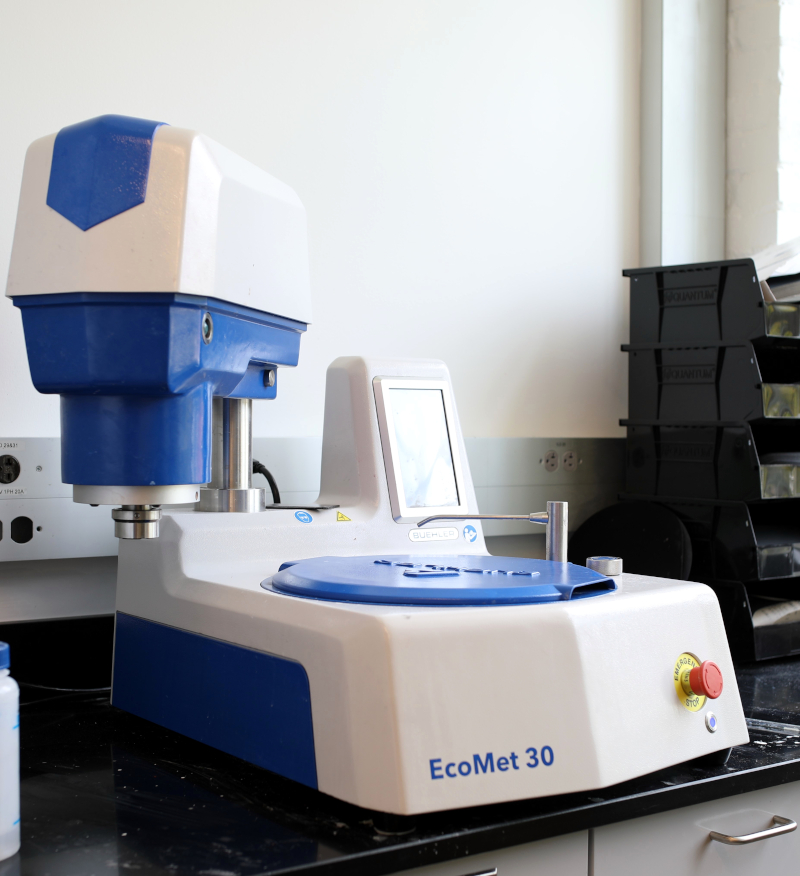

EcoMet TM 30 Semi-Automatic Grinder Polisher

The EcoMet 30 provides simple operations for routine grinding and polishing. The user-friendly touchscreen interface puts all regularly used functions on the front screen with no complicated menus that can add time to the process. Ideal for users who have a dedicated machine for each step in their process, the EcoMet 30 saves time with advanced cleaning features. Durability tested over 2500 hours and flexible enough to be compatible with 8in [203mm], 10in [254mm], and 12in [305mm] platens.

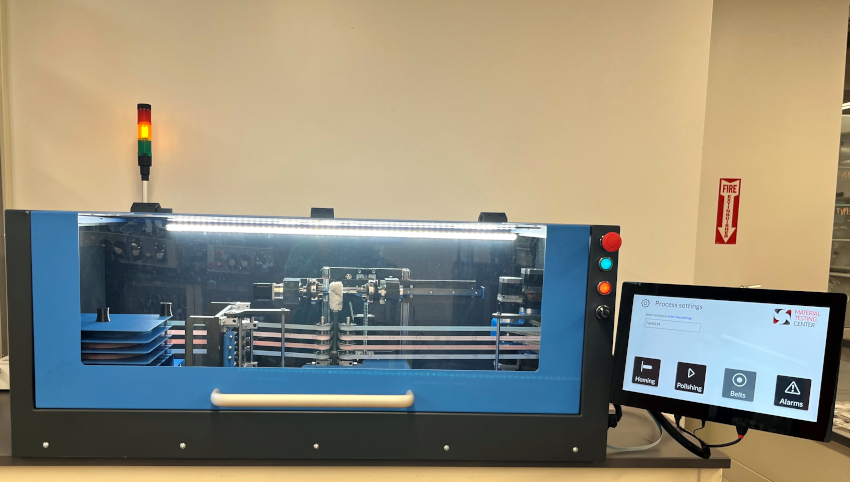

MTC Automatic Longitudinal Polishing System GR04

The longitudinal polisher ver. GR04 is designed to decrease grinding stress and surface residual stress after the initial processes of turning, milling, and grinding. The operation of our polishers is intuitive and controlled via a touchscreen application. The GR04 is the most advanced device in MTC’s portfolio.

-

- Electronic control of the process

- Longitudinal surface polishing

- Low-stress tooling

- Possibility of polishing different element geometry

FT4 Powder Rheometer

The FT4 is used to characterize the rheology of the powder (i.e., powder flow properties). This instrument is considered a universal powder flow tester. The FT4 is designed to simulate powder processing conditions (i.e., consolidated, moderately stressed, and aerated or fluidized states) and obtain dynamic flow (i.e., bulk and shear properties). This instrument has an unparalleled sensitivity which enables the differentiation of different powder batches. Sample sizes can vary from 10 to 160 ml. In the FT4, the resistance of the powder to flow is measured while the powder is in motion. The FT4 can be used for different categories of methodologies defined as Bulk, Dynamic Flow, Shear (according to ASTM D7891), and process. It can be used in many applications including pharmaceuticals, fine chemicals, food, cosmetics, toners, metals, ceramics, plastics, powder coating, cement, and additive manufacturing applications.

Thermal Characterization

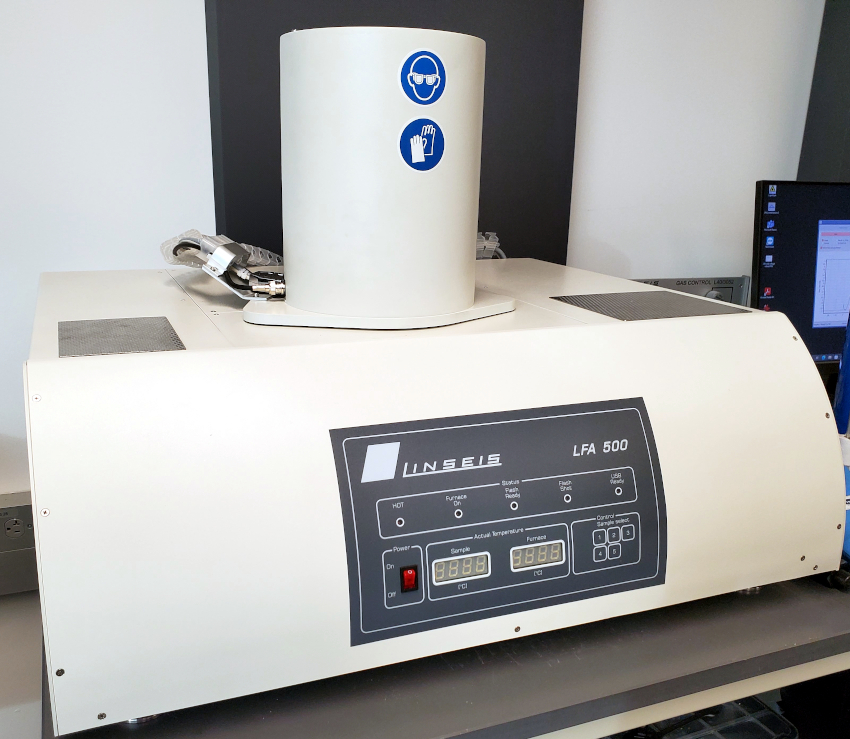

Linseis Laser Flash Analyzer 500

The Linseis Laser Flash Analyzer is used to measure the Thermal Diffusivity, Thermal Conductivity, and Specific Heat of solid samples from room temperature to 1500°C. It operates under a vacuum and can be run with an inert atmosphere such as argon or nitrogen. It can test up to five samples in one test run and has an accuracy of ± 5%.

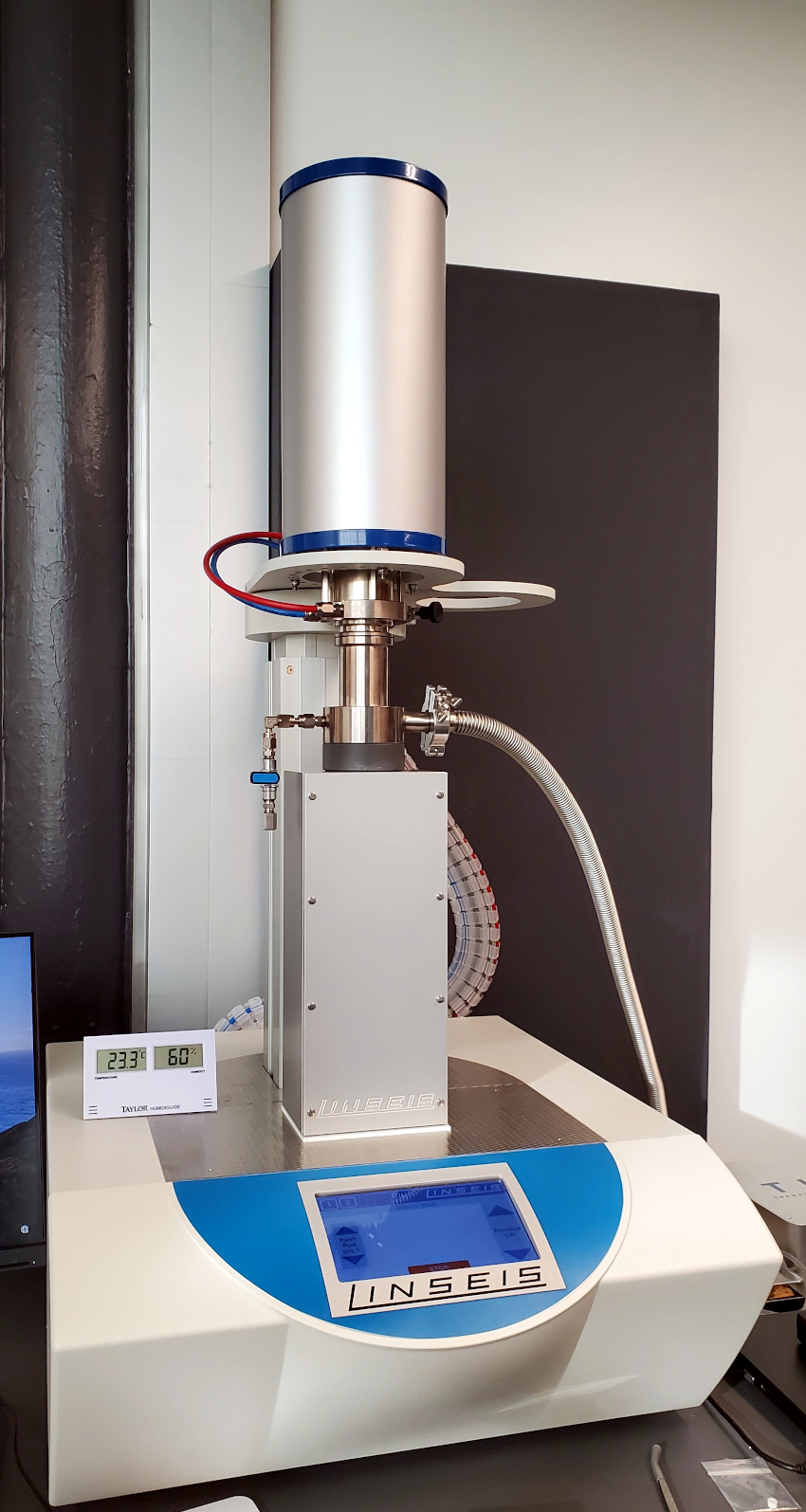

Linseis L75 Vertical Push Rod Dilatometer

The Linseis L75 Dilatometer is used to measure the Thermal Coefficient of Thermal Expansion of solid samples from room temperature to 1500°C. It operates under a vacuum and can be run with an inert atmosphere such as argon or nitrogen. It has a resolution of 0.125nm/digit.

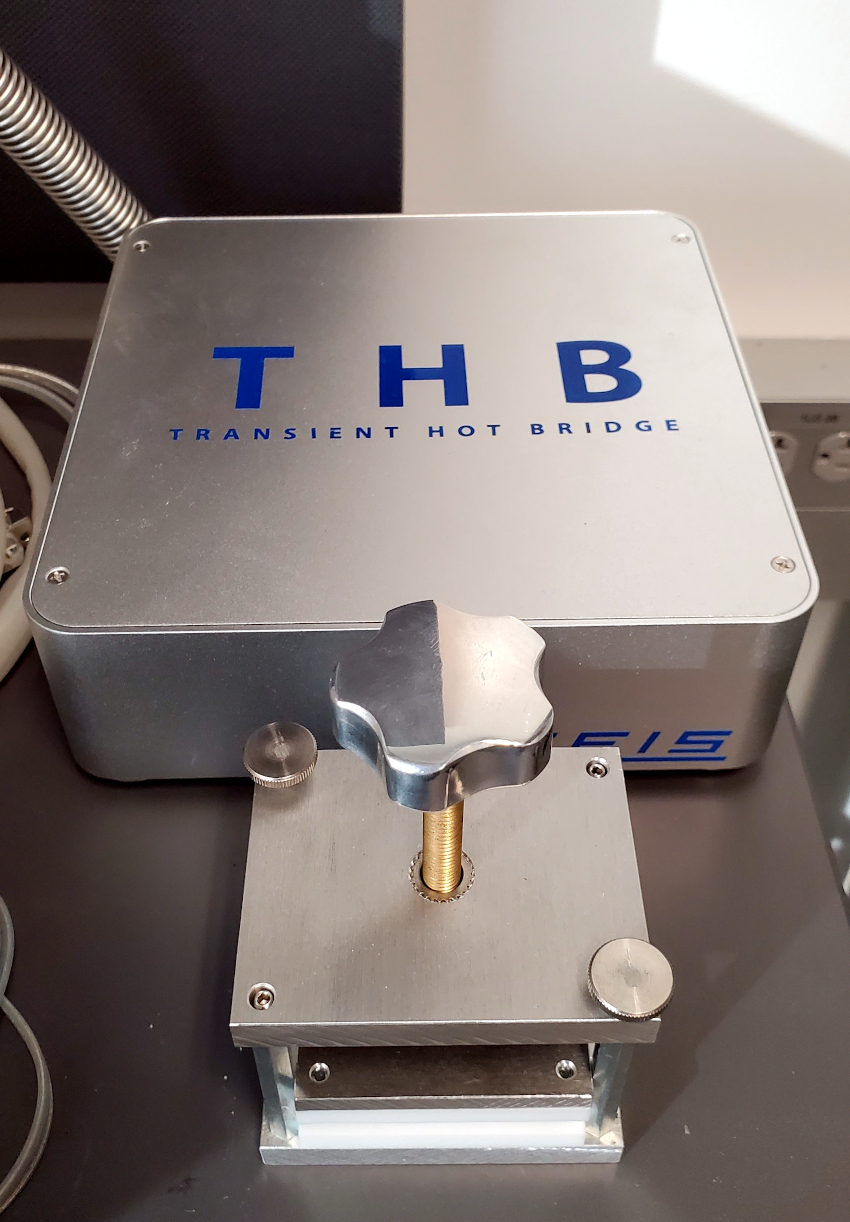

Linseis Thermal Hot Bridge (THB)

The Linseis Thermal Hot Bridge is used to measure the Thermal Diffusivity, Thermal Conductivity, and Specific Heat of solid samples at room temperature. This method is simple and fast, requiring little sample preparation and obtaining data within five minutes.

Heat TreatmentSENTRO TECH High-Temperature Tube Furnace

The 1200°C (2190°F) tube furnace provides accurate temperature control and safe operations. Hot enough for most laboratory applications, Sentro Tech's tube furnace is ideal for heating small samples. This furnace has many advantages including a 30-segment easy-use PID programmable temperature controller, long-life metallic heating elements, highly efficient ceramic fiber insulation, heating isolating ceramic tube, long-life K or S-type thermocouples, high-temperature sealing rubber sheet, etc.

Fisher Scientific

The 650-126 series Fisher Scientific Isotemp programmable muffle furnace is equipped with a single shell design with an operating range of ambient to 1125°C. The box furnace is designed to minimize outer surface temperatures while maintaining uniform heat distribution within the chamber.

SentroTech

The ST-1600°C high-temperature furnace is equipped with a double shell design to ensure low outside furnace temperature. This makes it ideal for dental, laboratory, universities, and any production scale applications. These furnaces are designed for accurate temperature control, excellent temperature uniformity, long-lasting performance, and safe operations. The temperature ranges up to 1600°C and operates with 208/240V.

Machine Shop

Milltronics SL6II CNC lathe

The Milltronics SL6-II is a CNC lathe fitted with a 6″ 3-jaw chuck, a maximum turning diameter of 12″, maximum turning length of 13″. This model has a 17 HP spindle motor and a 6,000 RPM spindle. Standard with a 12-station auto turret allowing for multiple machining tools to be fitted and improving machining productivity and efficiency. Programming and machine control are managed through Milltronics’ 9000 Series Controller.

Kent USA WSi 430 Wire EDM

The Kent USA WSi 430 Wire EDM is a submerge-type wire electro-discharge machine (EDM). Wire EDM is a non-contact cutting process that works on the principle of spark erosion between a wire and a part. Wire EDM results in high geometric accuracy and good surface finish of profile cutting. The submerge-type, such as the WSi 430 re beneficial for minimal noise and wire breakage and effective higher taper cutting – max angle of ±22.5° and allowing 5-axis control. The WSi 430 machine can accommodate workpieces up to 700 x 540 x 295 mm³ with a maximum weight of 500 kg. The machine is also equipped with an automatic wire threading system allowing for easy threading in the case of wire breaks.

Grizzly Industrial G9744Z2 Bandsaw

The Grizzly G9744Z2 metal cutting bandsaw can cut at angles ranging from 45-90°. The speed of cutting can be adjusted for different materials by changing the feed rate and feed pressure. Efficient cutting is achieved by using the blade tension indicator to produce good quality, straight cuts through the parts.

Grizzly Industrial Surface Grinder

The Grizzly G5963 surface grinder can resurface metallic plates to give high-tolerance flat surfaces, ready to be used in additive manufacturing applications. Workpieces can be mounted to the magnetic table and maneuvered in the x and y direction. The grinding wheel moves on the vertical axis and allows small pieces of material to be removed, giving high-precision surfaces.

Pace Technologies MEGA-M250 Abrasive Saw

The Pace Technologies MEGA-M250 abrasive cutter features a 250mm blade capable of cutting samples up to 75mm in diameter. The MEGA vices allow small samples to be secured allowing precision cuts to be made. The abrasive blades can be changed depending on the specific needs.